Vacuum technology paved the way for various technological achievements of the past century and is a key enabling technology of the 21st century. Global cross-industry trends such as nanotechnology are leading to ever lower pressure ranges and thus higher demands on the vacuum technology components installed.

Vacuum-optimizing screws are needed in all industries where high to very high demands are placed on the vacuum environment. Particularly in high vacuum pressure ranges from <1E-6 mbar, virtual leaks, i.e. gases trapped in cavities, have a massive effect on the process pressure, the service life of the system and the contamination of the vacuum. Users should therefore avoid trapped gas volumes in their vacuum systems. With the help of our vented screws, you can very efficiently and cost-effectively vent blind holes of screw connections.

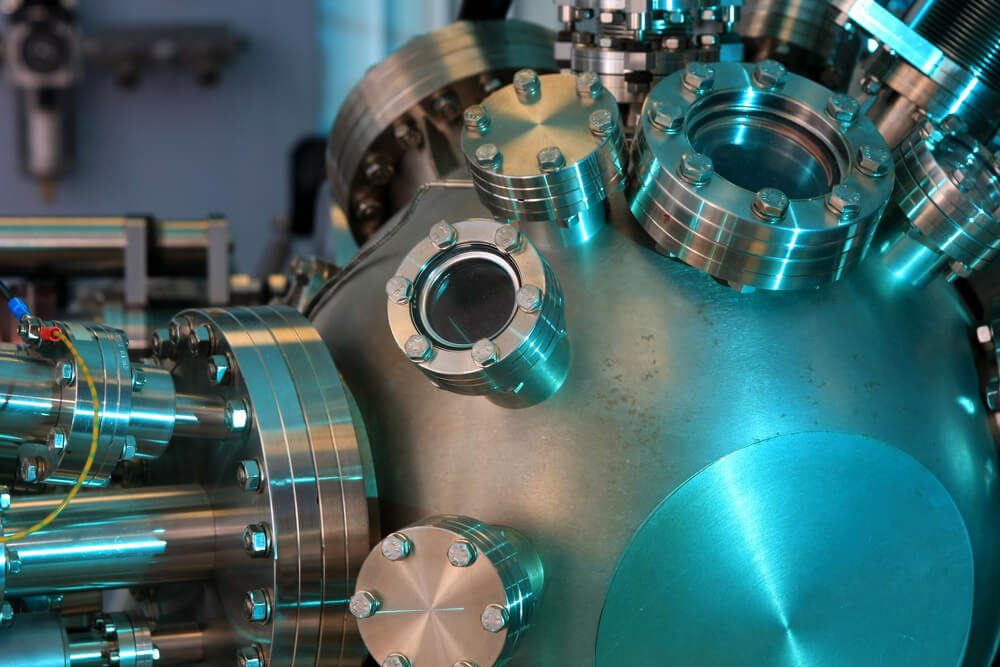

As one of the largest application areas for vacuum technology, analysis technology encompasses all applications that require a vacuum to perform. Whether electron microscopy, mass spectrometry, surface analysis, metrology and many others – all of them are united by the high demands placed on the installed vacuum components. In this market, equipment manufacturers and users rely on vacuum screws to eliminate as many disturbing factors as possible in the vacuum application. After all, only with optimal process conditions can the limits of what is possible be pushed and disruptive scientific findings be obtained.

Functional or decorative coatings on products such as fiber optics, lenses or displays and screens are applied under defined vacuum conditions. All these coatings require high-precision components for a reliable process flow. VOC vacuum screws are used to assemble superstructures in the coating systems. Use our vacuum optimizing screws analog to your existing standard screws and benefit from an optimized vacuum environment without design changes.

In many areas of semiconductor manufacturing, an ultra-high vacuum (UHV) is indispensable to reliably avoid disruptive substances in the process. To produce state-of-the-art microchips, it requires a vacuum environment where process pressure is safely maintained and no substances outgas into the vacuum. With the help of VOC vacuum screws, users effectively eliminate virtual leaks in blind thread holes and are a big step closer to process-safe production.

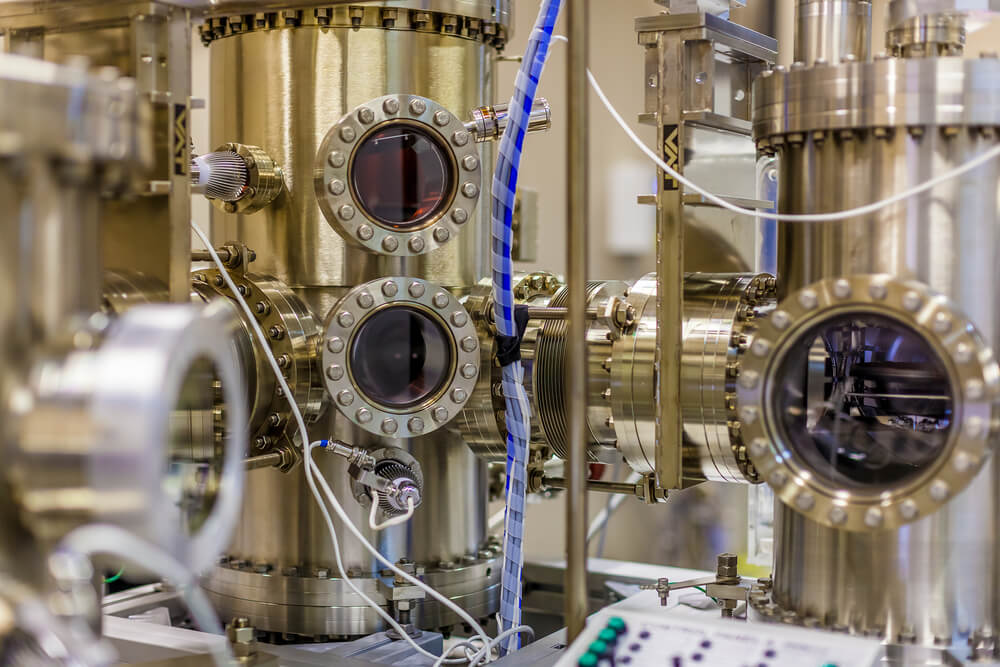

Led by the extensive application area of basic research (including particle accelerators), the scientific community represents one of the largest users of vacuum technology. But not only in particle accelerators, where the connections of the universe are explored, but also in other research areas such as quantum computing, plasma physics, photonics, space research and many more, vented screws are used to set up the vacuum experiments.

Discover our wide range of vacuum-optimizing fasteners.

VOC – Vacuum Optimizing Components GmbH is a leading supplier of vacuum screws that efficiently protect against virtual leaks. Our diverse range, available in our online store, serves all industries with high and ultra-high vacuum requirements.

Further links

Contact us

Moritz-von-Rohr-Strasse 1A

07745 Jena

Germany

Our partners

© 2024 VOC – Vacuum Optimizing Components GmbH. All rights reserved.